How India makes steel for the world

Steel is used in many economic activities. Steel industry has a multiplier effect on the economy. This is an overview of this large and heavy industry.

Total Views |

In today’s industrialized world, steel is an essential material for producing many products. From many luxurious products like cars, motorcycles, and heavy machinery to things that we use daily, steel is used in various forms. A variety of steel is used in various industries ranging from transportation, energy, and infrastructure. As steel is used in all these industries, changes in steel prices and production impact all these industries. Therefore, even if the steel industry independently has less impact on the economy, employment, etc it triggers a multiplier effect in the economy, hence it is an important driving factor of the Indian economy and India’s GDP growth.

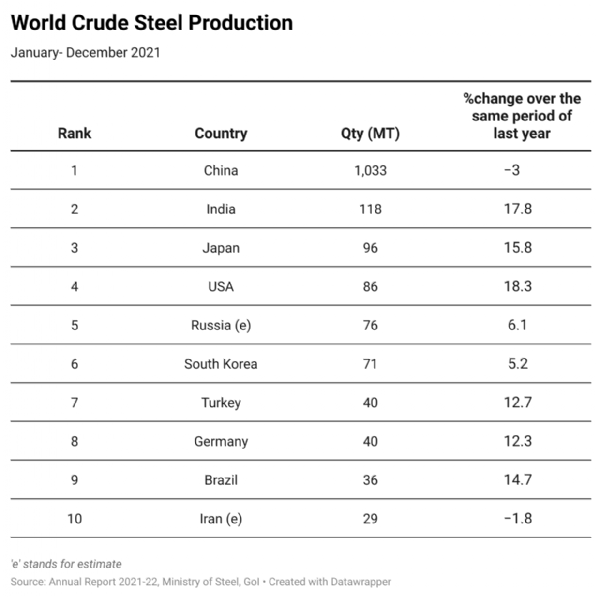

In the global scenario, China is the largest producer and exporter of steel. As per IBEF report in FY2020-21 India was the second largest producer and consumer of crude and finished steel. The same report also states that, as per the World Steel Association Steel Authority of India (SAIL), Tata Steel and Jindal Steel Works (JSW) were on the list of the top twenty-five steel-producing companies.

Steel Producers and Steel Plants in India

Steel production is a very capital-intensive business. It needs a high level of technology, an efficient supply of raw materials, a highly skilled workforce, large land spaces, etc. It is also a very heavy industry. Therefore, companies that have high capital can invest in this industry. In India, there are several private players in this sector.

Also Read: India’s Green Energy Story

India has a long tradition of metallurgy according to some articles steel processing in India is an ancient practice. It is said that there are remnants of furnaces in some archaeological excavations, but the foundation of the modern steel production industry was laid by Tatas. Prior to that, there were other producers like Bengal Iron Works which founded the first blast furnace and started steel production in 1874. Yantra India Limited started its two furnaces at Gun & Shell Factory (GSF) and Metal & Steel Factory (MSF) at Kolkata (then Calcutta).

Tata Iron and Steel Company (TISCO) was established by Sir Dorabji Tata as a part of his father's conglomerate in 1907 in Jharkhand originally Sakchi; which was later in 1919 renamed as Jamshedpur in the honor of its founder Jamshedji Nuserwanji Tata. In 1939, it became the largest steel plant in the British empire. Today, it is one of the largest steel manufacturers in India.

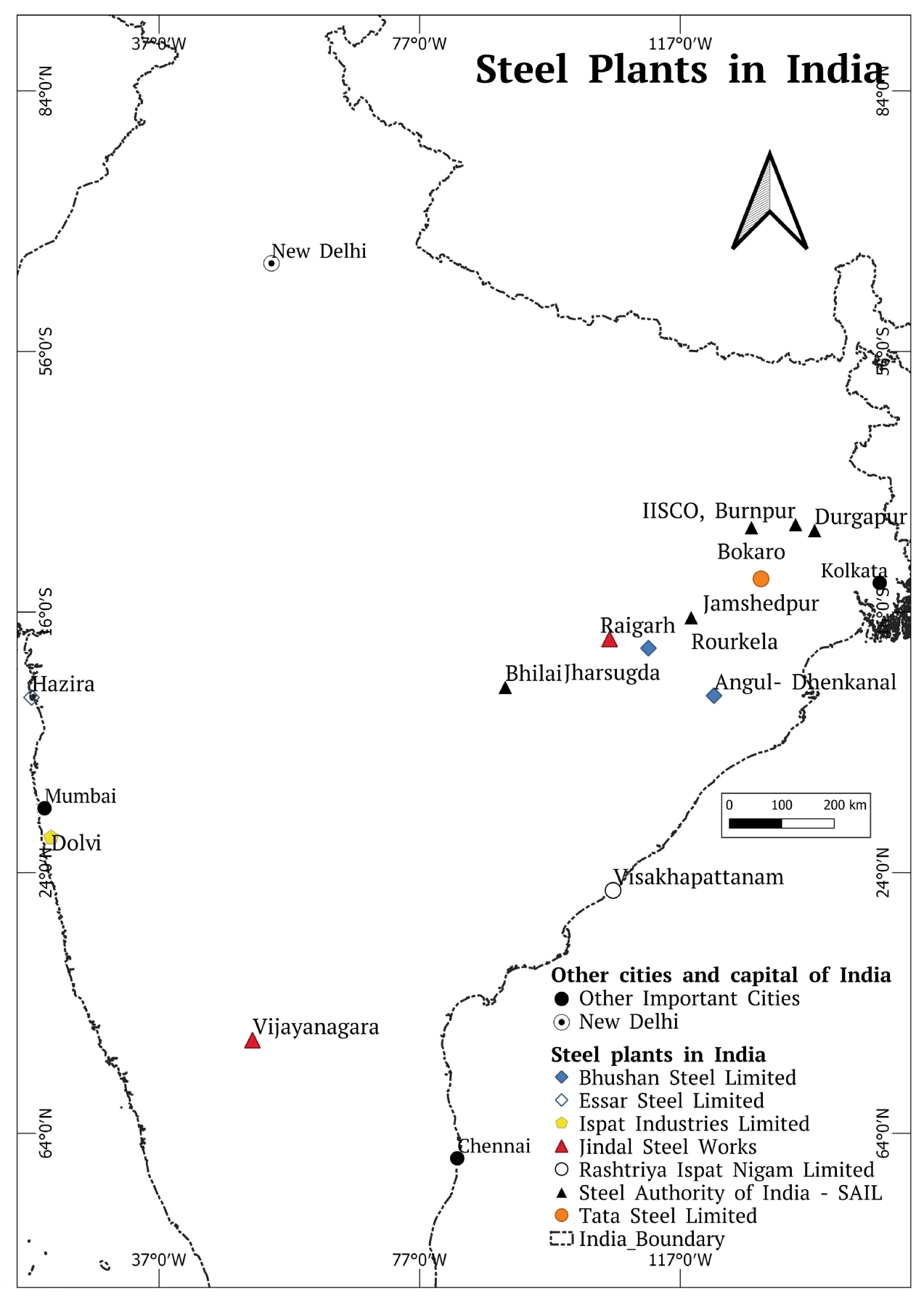

Along with Tata, there are some other private players like Jindal Steel Works limited. Bhushan Steel Works; which was taken over by Tata Steel in 2018. The government of India established the Ministry of Steel and established its steel plants. Steel Authority of India and Rashtriya Ispat Nigam Ltd. operates steel plants at various locations all over India. The following map shows the locations of steel plants in India. In the map, Bhushan Steel Work plants are shown independently. The map is based on information received from Press Information Bureau’s November 24, 2011 release. Also, these are not the only plants in India. There are several other small plants, these are highlighted plants in India.

Steel production requires water during the production process. Coal, Iron ore are other requirements for production. Therefore, as we can see the plants are concentrated in eastern parts of India, primarily on the Chhota Nagpur plateau, where minerals are available in large amounts. Also, Ganga is the primary river available in this region, with its other tributaries. These rivers and other water sources fulfill the need for water too.

Also Read: India’s Grains Story

Steel Production, Import, and Export

In the last few years, India is increasing its steel production. As we have read in the beginning, steel is required in various engineering industries. According to some reports, recently India has overtaken Japan and had become the third-largest producer of steel in the world. The following table shows the top 10 producers of crude steel in the world.

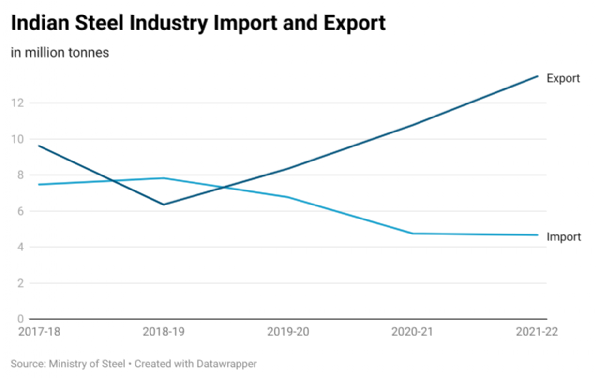

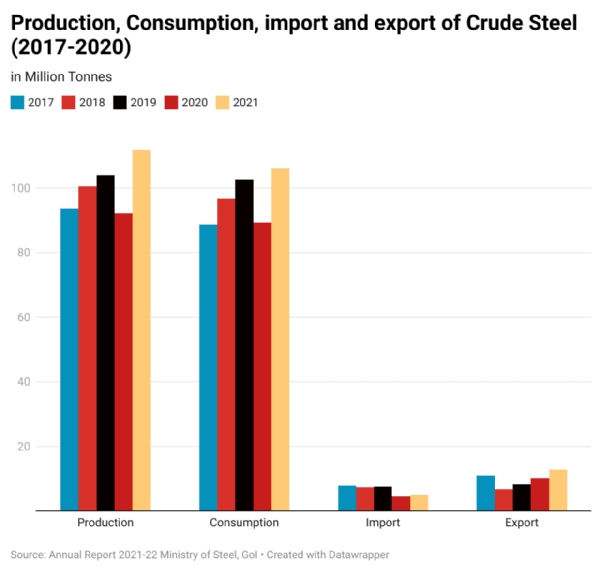

As India is also one of the largest steel producers, it exports steel and imports it as well. Since 2017, the import of steel by India has decreased and on the other hand, India is exporting more and more steel. The following diagram shows the relationship between the import and export of steel from India.

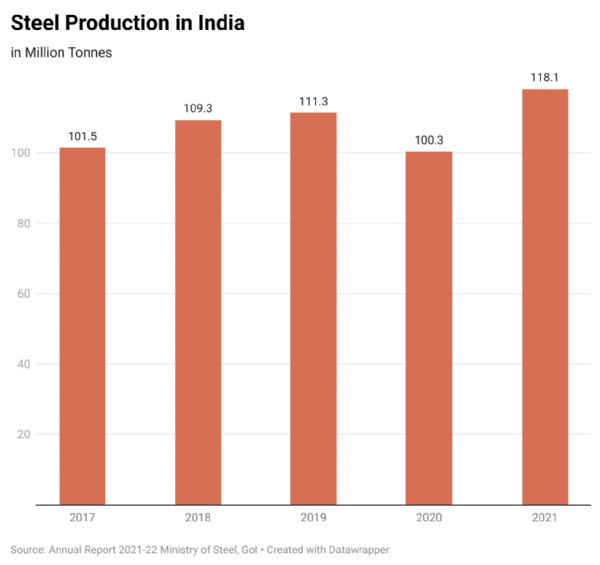

India’s steel production has increased since 2017. As per the Annual Report 2021-22, Ministry of Steel Government of India, in the year 2021 the steel production in India was 118.1 million tonnes. Refer to the following graph for the production of steel in India.

Along with production, the consumption of steel has also increased over the years. The following graph shows the pattern of production, consumption, import, and export.

Also Read: India in Space

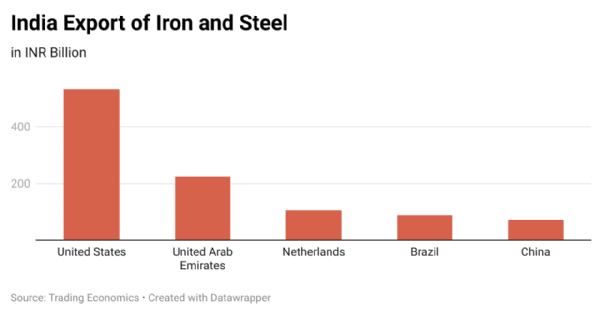

India exports steel to various nations. As per Trade Economics data Aug 22, the largest importer of Indian steel was the United States. It was then followed by the UAE, Netherlands, Brazil, and China.

Policies and taxes

The government of India has been promoting steel production through various policies. Not only the production but also the reuse of scrapped steel is being promoted in India through various policies like the vehicle scrappage policy.

As per the IBEF report, some reform measures taken by the Government of India were as follows.

- FDI- The government of India allowed up to 100% FDI in the steel sector for better growth.

- National Steel Policy (NSP)- In 2017 Government of India made a policy to boost the steel industry through measures such as meeting domestic steel demand. The aim was to increase per capita steel consumption from 74.1kgs (2018-19) to 160 kgs by 2030-31 and also to grow steel-making capacity from 142 MT per annum (MTPA)(2018-19) to 300 MTPA in 2030-31.

- Steel Scrapping Recycling Policy (SSRP), 2019- The government of India designed a policy to promote the use of recycling and reuse of high-quality steel. The policy provided a framework for scientific segregation, collection processing, etc.

- Other Initiatives- Along with these policies government promoted steel production in India through various other policies.

Also Read: Aarey Carshed and Environmentalism

We have now seen how steel is important and also that India is the second largest producer of steel. It is also clear by now that, India’s steel exports (may be lesser than some other countries) are a considerable amount. More than that, as steel impacts other sectors of the economy, taxes imposed or levied on steel affect the whole economy to some extent. In May 2022, the Government of India imposed an export tax on various steel products to improve the supply of steel in the domestic market. Since then, steel producers are in a long wait for the government to waive the export duties on steel products to boost the steel export. The government of India has not yet taken any decision on this matter, but whenever it takes the decision, it will impact widely on the economy.